PRICE$3,750.00

| PRICE | $3,750.00 |

|---|---|

| AVG, SHIPPING TIME Timing is based on our current production timeline. | |

| PRICE | $3,750.00 |

|---|---|

| AVG, SHIPPING TIME Timing is based on our current production timeline. | |

01 - HANDMADE IN USA

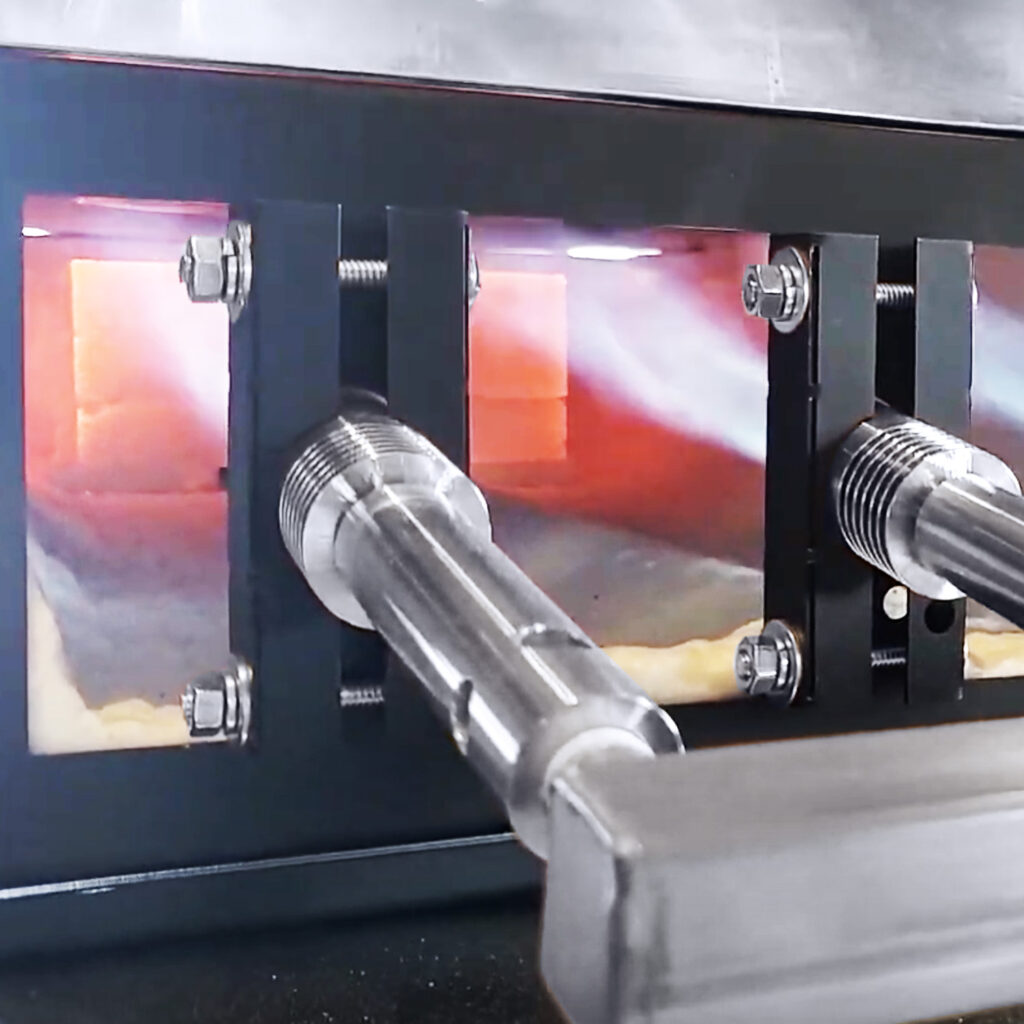

Explore how this evaporator works. Learn more about propane vs natural gas versions. Get helpful tips and resources for getting the most out of your evaporator.

02 - FIND THE PERFECT FIT

To recommend the best evaporator for you, we should consider a variety of criteria such as size, evaporation rate, fuel type and budget.

Take advantage of our online resource library, 24/7. You’ll find illustrated instruction guides, videos, and a full range of maple topics!